Solar Power Inverter

An automobile industry was facing high incident of harmonic failure in SCADA, motor drive & electrical equipment after installing 1MW solar power inverter. The rated capacity of 1.0MW DC solar power is evacuated through 16Nos, 50kW, 3Phase, 415Volts, 50Hz solar string inverter which itself got affected with the harmonic problem. While designing the solar string inverter a 20% power loss is considered by the solar panel manufacturer for conversion from DC solar panel power to AC power delivered in the 3Ph, 415V, 50Hz electrical power grid. Every day during the peak solar power generation when the sun is at the top of the sky, randomly one inverter trips and remains switched off for several hours. It causes a loss of 3 to 5% in the solar power generation by considering that the inverter trips at the most productive time. The solar power inverters diagnose it as over voltage tripping. But during the root cause analysis carried out before installing harmonic filter, we did not find any over voltage problem in the factory's electrical power system. We designed the harmonic filter for troubleshooting the factory's electrical and electronic equipment failure as well as providing a photo voltaic solar string inverter solution by mitigating its over voltage tripping condition.

Solar Panel - specification

1. Solar panel module type: Crystallure Silicon Photovoltaic Modules

2. No of Solar Panels installed: 3100 nos

3. Solar Panel installation method: 22-deg raised angle from ground at North-South direction and the North end raised.

4. Each solar panel's Peak power delivery capacity Pmax: 320 kWp

5. Rated installed capacity in kWdc: 3100 x 320 = 992 kW

6. Average yearly generation for the total installed capacity kWdc: 17% (Estimated)

7. Open CKT voltage (Voc): 46.22 Vdc

8. Max. Power voltage (Vmp): 37.38 Vdc

9. Short Circuit current (Isc): 9.06 Amps

10. Max power current (Imp): 8.56 Amp

11. Max System voltage: 1000 volts

12. Manufacturing Standard: IEC 61215/ 61730

Solar Power inverter - specification

1. Each Solar Power Inverter's AC power output max: 50kW, 415V, 3Ph, 50Hz

2. Total nos of outdoor inverters (IP65) installed: 16 nos

3. Max AC power delivery at the low voltage electrical grid: 16x 50 = 800 kW

4. From DC solar panel power to AC grid delivery conversion losses: 20%

5. Nos of solar panels at each DC input String: 20 panels in Series, 924.4 to 747.6 Vdc

6. Nos of DC input Strings in parallel: 10 nos, each parallel string is at 900Vdc.

7. Total Nos of Panels and kWdc at each solar Inverter: 200 solar panels x 320 kW= 64 kWdc at each Solar Inverter.

8. DC input: 200 to 1000 Vdc (max), MPPT= 520 to 800 Vdc

9. DC Short Time current Max: 2x 50 Amp

10. DC Short Circuit current: 2x 60 Amps

11. Solar Inverter AC Power Output: 3P3W or 3P4W, 50/60Hz, Normal: 50 kW/ 50 KVA, Max: 55 kW/ 55 KVA and Imax: 80 Amp

Solar Power Inverter - Grid Connectivity

Each solar string inverter is connected with 200 nos solar panels each of 320 Wdc capacity. Totally the solar inverter collects 64 kWdc power at its input and converts it into 3Ph, 50Hz, 50 kWac power at its output as shown in Fig.2. The main ACDB is connected with 16 nos solar inverters wherein all are paralleled. Totally it connects to 3Ph, 50Hz, 800 kWac power load as shown in Fig.1. Finally the main ACDB is connected at the 2500KVA, 22kV/ 0.415kV transformer's main LV PCC panel with a 2000A, 415V ACB for total 800 kWac power delivery at the factory's electrical power system.

Ever since the installation of 1.0 MW solar plant, this automobile factory had started facing substantial increase in nuisance tripping and failure in electronics, drives and electrical equipment.

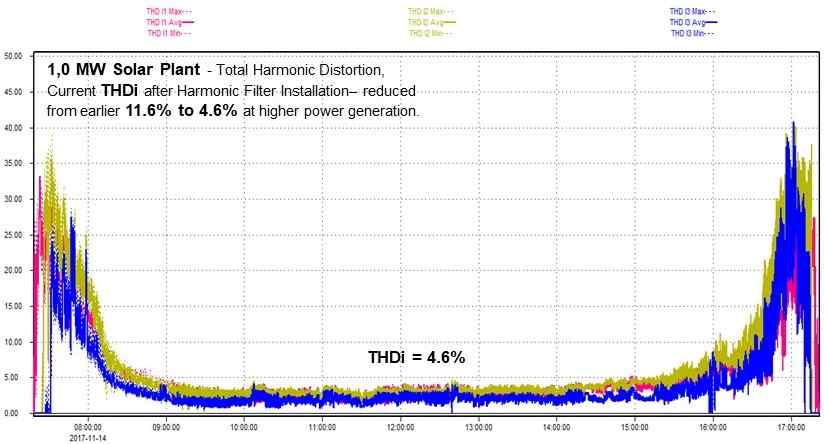

While carrying out harmonic audit we observed that the total current harmonic distortion (THDi) at the 415V main incomer of 2500KVA transformer-2 was at 40% and the total voltage harmonic distortion (THDv) was at 10%. The current harmonics coming from the 1.0 MW solar plant, which is connected at the downstream of the transformer-2, was at 11.6% during full solar power generation period when the sun is at the top.

Harmonics apart, it caused stressful power quality problem. The transient voltage fluctuation and voltage sag recorded was at an unacceptable level of 17.7% and the transient current fluctuation was at a dangerous level of 100% rise over its steady-state base load. Harmonic failure apart, it increased end-product quality-check rejection and also increased scrap generation from the manufacturing process.

A 1407A Encon Harmonic Filter is installed during Nov. 2017 at the 415V main incomer PCC of 2500KVA transformer-2. It's designed for the full transformer-2 load including the 1.0 MW solar power harmonic at the downstream of transformer-2. Passive harmonic filter being a harmonic absorption type, engulfs harmonics from both downstream as well as upstream within its range.

Without the harmonic filter, a portion of the current harmonic circulates and gets absorbed within the plant equipment, and the other portion flows back to the upstream power grid. Since the electrical and electronic equipment in a plant are not designed for the high frequency harmonic currents, plant equipment get overloaded and trip many a times. In its dormant stage the harmonic injects energy losses. The higher current harmonics within the plant equipment create higher voltage harmonics which in turn generate further current harmonic.

Thus, the current harmonic increases with the increase in non-linear-load within the same transformer. This is the root case why the addition of 1.0 MW Solar Plant in transformer-2, substantially increased the nuisance tripping, failure and reject scrap generation in this automobile industry. Summarily, it increased both current and voltage harmonics within the transformer's electrical power system wherein the plant equipment are connected.

With the commissioning of the harmonic filter, the current harmonic got slashed from 40% to 6% and voltage harmonic got reduced from 10% to 2% level. This harmonic reduction case study is delineated in an another web page, please read it at Passive Harmonic Filter.

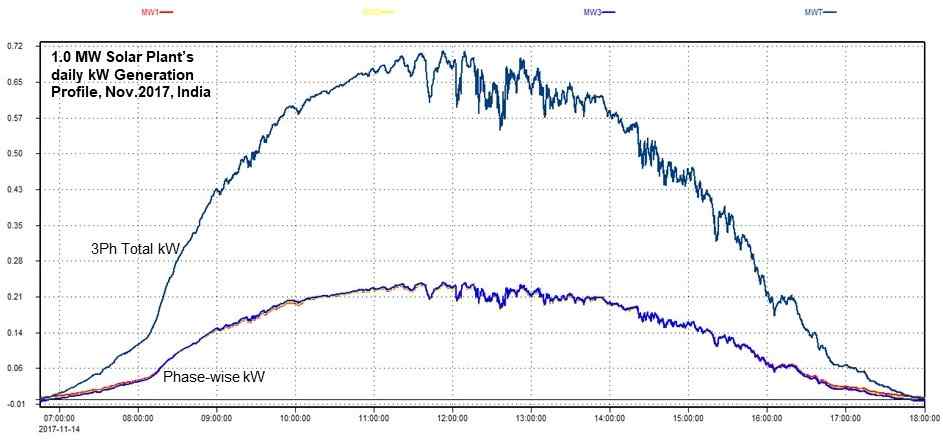

Even though the solar plant was connected at the downstream of the transformer-2, as reasoned above, the current harmonic generation from the solar power inverter got reduced from 11.6% to 4.6% at full load, as shown in Fig.5. A typical day's energy (kW) generation profile from this 1,0 MW solar plant, after the installation of harmonic filter, is shown in Fig.3.

The harmonic filter is connected at the 415V main incomer of 2500KVA transformer-2 is shown in Fig.4. The harmonic filter has eliminated the daily harmonic problem of nuisance tripping with solar power inverter. And together by slashing it's harmonic generation it is expected to increase the overall solar plant efficiency and enhance its power generation capacity in kWh terms by 8%.

Within a few days after commissioning the Harmonic Filter at this automobile industry, we were interacting with the shop floor electrical supervisor. He informed us that in the previous night while he was on a night shift duty the plant lights dimmed due to grid voltage fluctuation. From his experience he knew that it's going to be a bad day and invariably the big machines, the Inter-Mixers with 400kW VFD drives, would trip and along with it there would be several tripping in the process lines involving several VFD drives, HMI and SCADA. As usual he ran towards the Inter-Mixer Drives and his other team members ran towards other process areas. He and his team members are the first line of defense against voltage sag tripping. He was surprised and was wondering why nothing has tripped? For this good reason we describe Encon harmonic filter as an Electrical Fly Wheel. It's designed with energy storage devices and those are very useful in mitigating momentary voltage sag. Over the past 25-years we have learned that 80 to 90% nuisance tripping get eliminated after installation of Encon Harmonic Filter. That apart, by slashing harmonics, both voltage and current, it eliminates 80 to 90% failures with electronics, drives and electrical equipment.