Total Harmonic Distortion

When a plant with high NLL runs at full load, it crams harmonics and active power in the power system, causing unacceptable energy surge wherein harmonic distortion is the ratio of harmonics to fundamental frequency (f1 -50Hz) component. Total harmonic distortion (THDv, voltage) and distortion factor are related terms defined by a ratio of square root sum of all high-frequency harmonic voltage-squares (v2, v3, v4, and so on) to fundamental frequency (v1) voltage.

While defining Total harmonic distortion (THDi, current), it merely represents a unit of harmonic distortion and not the extent or measure of harmonic distortions. THDi is a ratio of square root sum of all high-frequency harmonic current-squares (I2, I3, I4, and so on) to fundamental frequency (I1) current.

The fundamental-frequency power (50Hz) is the active power that does all the real work and drives plants and machinery. On the other hand, the high-frequency harmonics, in the integer multiple (2x50Hz, 3x50Hz, and so no) of fundamental-frequency (50Hz), do no real work and get wasted by causing heat loss in plant equipment.

Understanding Harmonic Distortion

What causes harmonic distortion? It's Non-linear load and impedance of the power system. What are the types of harmonic distortions? While THDi (current) and THDv (voltage) are the two types, Total Demand Distortion (TDD) calculates the extent and measure of THDi. How much harmonic distortion is acceptable? When harmonic distortion causes power problems and equipment failure?

1. Non-Linear loads like DC drives, VFD Drives etc., generate harmonic currents in integer multiples of fundamental frequency (I2=2x50Hz, I3=3x50Hz, and so on). Summarily, total current harmonic distortion (THDi) is a measure of these current harmonics.

2. One part of the generated harmonic currents circulate to all connected equipment within its electrical power system, causing harmonic stress that gets wasted as heat loss, equipment failure and unwanted tripping. Another part flows upstream through the transformer towards the grid. This harmonic current flow in the respective equipment and branches follows Ohm's law which is inversely proportional to their impedances.

3. As the generated harmonic currents flow through branches of the electrical power system, it's impeded by their circuit impedance and cause voltage drops. The second harmonic current (i2) causes a second-harmonic voltage (v2) drop, the third harmonic current (i3) causes a third harmonic (v3) voltage drop, and so on. Summarily, it causes a total voltage harmonic distortion (THDv) by these related current harmonic induced voltage drops.

4. The generated current harmonics THDi is the cause. The induced voltage drops, which create voltage harmonics THDv, is the effect. The extent of voltage distortions THDv depends on two parameters. The first one is the magnitude of THDi and the second one is the impedance value of the power system.

5. Thus, THDi is a unit of current harmonic distortions, and its magnitude alone does not necessarily mean a beyond limit high harmonic distortion. Accordingly, a high percentage THDi value alone does not automatically mandate a harmonic distortion correction measure or the need for harmonic filter installation.

6. On the other hand, THDv is both a unit of voltage harmonic distortion and a sum of all voltage harmonics drop. It reasonably indicates the extent and measure of Harmonic Distortion in a power system. A high percentage THDv suggests a high harmonic distortion level in the power system.

7. The real Harmonic Distortion problem arises when an electrical power system with a high percentage of non-linear loads operates close to the rated load of its supply transformer (or diesel generator) capacity. It would generate a high percentage of THDi. In turn, that would result in a high THDv value. On the other hand, if a transformer is lightly loaded and has non-linear loads, the power system and the transformer still possess some capacity to absorb harmonic currents. Thus, harmonic failure with a sparsely loaded transformer is not common, even with a high THDi value.

The Harmonic Distortion Filter is not a mass manufacturing process. It's a custom design engineering process for the manufacturers of power quality filters.

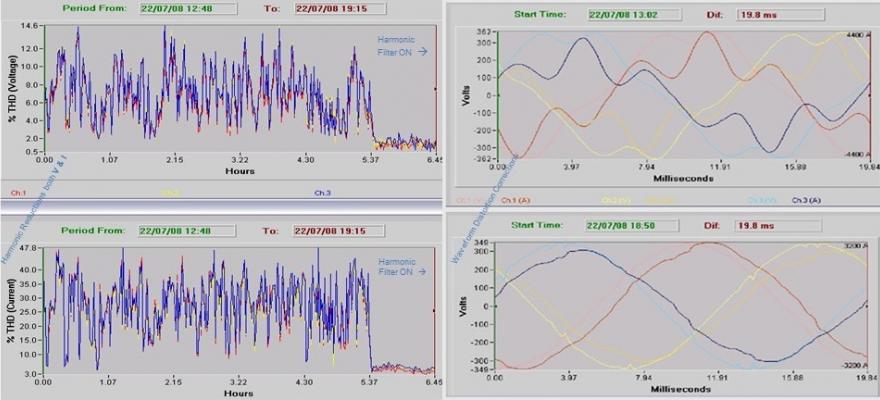

1. Limit both THDv (Total Voltage Harmonic Distortions) and THDi (Total Current Harmonic distortions) and reconstruct distorted waveform back into Sine Wave, as shown in the caption picture above, a technology that improves and transforms the fuel guzzling, bad power quality dirty power into Clean Quality Power.

2. Enhance quality of finished products since torque vibrations across plant and machineries get eliminated. Slash quality check rejections for final products. Eliminate equipment tripping and failures, slashing down mean time between failures (MTBF). Enhance plant's 3P, Power, Productivity, and Profitability.

3. Debottleneck equipment capacity limitation with Non-Linear-Loads, allowing increased Load Factor up to rated capacity, sustainably for all equipment from captive power plants (TG or DG), transformers, switchgears, ac/dc drives, ac motors-SQIM/SRIM, dc motors to cables and terminations. Reduce equipment sizing substantially, slashing both project investment costs and running energy bills.

4. Eliminate equipment maloperation across all industrial, commercial and building operations. For example, it eliminates building elevator uneven floor landing with the landing floor, and in-addition its erratic operations.

5. Eliminate tripping in plant equipment, drives, and process loads due to voltage fluctuations/ sags that originate from either external grid source or internal power system.

6. Eliminate building's electrical fire risk due to excessive third harmonic current (also called zero sequence harmonic current) which add up to neutral, and any infirmness in neutral is a very serious fire hazard.

7. Eliminate overheating in equipment, drives, process loads, cables, and terminations.

8. Eliminate failures with plant and machineries.

9. Automatically maintain unity PF eliminating the need for a separate capacitor panel, which with nonlinear loads magnify harmonics and further complicate the harmonic problem.

10. Lower equipment footprint allows space savings. Lower carbon footprint reduces global warming effect. Slash down both with equipment maintenance and AMC costs.