Passive Harmonic Filter

With a passive harmonic filter, the harmonics reduce by absorbing it from the downstream load. It relieves harmonic stress on load end equipment and solves its failure and tripping problem. It permits the plant to achieve a full load run with reduced energy consumption. Encon facilitates the best harmonic solutions. Engineers worldwide depend on passive harmonic filters when the electric load is sizeable, harmonic distortions alarming and yet there's a need to slash equipment footprint by designing a rated load plant operation.

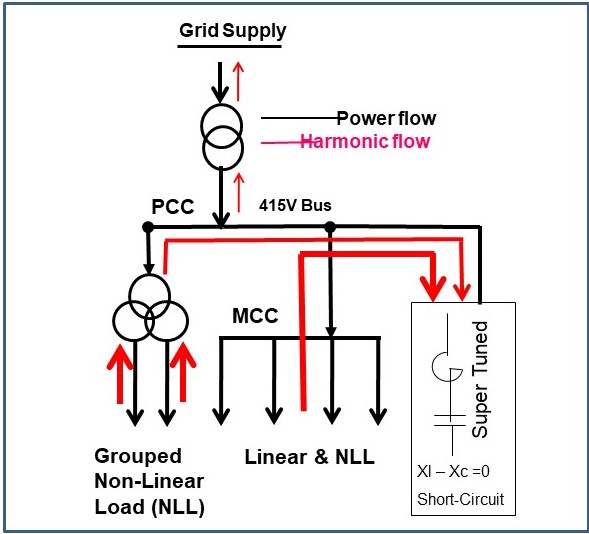

Unlike the ineffective series passive harmonic filter, the highly effective passive harmonic filters are always parallel type harmonic filter. It eliminates load generated harmonics by drawing them towards it creating a short circuit path, and then absorbing harmonic within it. It thus eliminates the need for equipment derating even with extreme harmonic distortions and allows plant operation at a hundred percentage loading for all plant machinery.

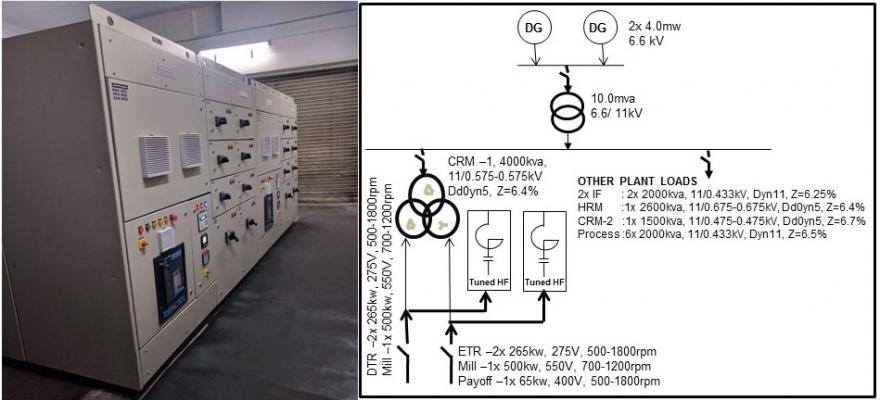

Unlike an active harmonic filter which comes in small ratings, the shunt passive harmonic filters are both of low and high powered specifications. Besides, it's flexible for any input voltage design covering the complete working voltage range of plant equipment from as low as 120 volts to 36 kV. It enhances the plant's 3P, power, productivity and profitability by manifold. We manufacture the most valued passive harmonic filter of type Super Tuned which is a top-end custom-built product.

When you have a harmonic problem, repetitive failure in process drives, electronics, servers and electrical equipment or unwanted tripping, the passive harmonic filter will solve all your problems. Needless to say, that it will mitigate both voltage and current harmonics to tolerable limits within IEEE-519 standard. A super tuned passive harmonic filter is of high power capacity that reduces extremely high harmonic distortions in both voltage and current waveforms within a safe working limit. Thus, it also identifies as a harmonic distortion filter.

There are few other variants of a passive harmonic filter. They are series type passive harmonic filter, detuned harmonic filter and triplen harmonic filter. The series passive harmonic filter introduces an impedance before an individual load that reduce little current harmonics by the principle of ohm's law. It seems to work without causing an equipment tripping problem when a transformer has very few non-linear-loads. Series harmonic filter finds its application connected in series, with a smaller non-linear-load, within a much bigger transformer wherein harmonics are anyway within IEEE-519 limits, thus indicating it as IEEE harmonic filter. But, by doing so, it increases power system impedance and thus the voltage harmonics, which could cause tripping in sensitive electronics and VFD drives with even minor voltage fluctuation if there are sizeable series harmonic filters within a transformer.

A detuned harmonic filter does not mitigate harmonics but improves power-factor (PF). When it's added to an electrical power system it creates two paths. One path is into the filter, and another towards the source. The harmonic current does not flow into the detuned harmonic filter path as it offers a high impedance path and diverts into the low impedance source as per the current divider rule of the ohm's law.

A triplen harmonic filter eliminates neutral harmonic current and reduces the high neutral voltage of an electrical power system. It finds application in Data centre server, automation system, electronic gadgets, and large LED light installations, which generate high neutral harmonic currents wherein the current in the neutral wire equals the phase current. It further increases the neutral voltage. It has few names being a neutral current eliminator, zero-sequence harmonic filter and third harmonic filter.

How Passive Harmonic Filter prevents equipment failure from harmonic flow?

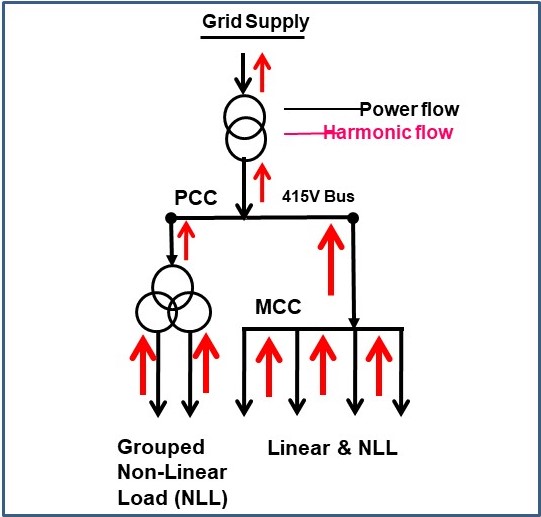

1. Harmonic being a Current Source, flows in the opposite direction of normal power flow. Harmonics flow from the downstream non-linear-loads into all branches of the upstream power system wherein it distributes in inverse proportion to the respective electrical branch impedance.

2. By Ohm’s Law, the harmonic current flows across all feeder paths of an electrical power system based on each path’s relative impedance. Along the harmonic flow path, two events happen.

3. First, the downstream equipment and cables, designed for a fundamental frequency of 50/ 60Hz, absorb these high-frequency harmonic currents, which cause excessive stress to themselves. It results in equipment failure, high drive temp, unwanted tripping and malfunction of sensitive equipment. When harmonics are excessive, only a super tuned passive harmonic filter can effectively solve these harmonic problems. The super tuning creates a strong short-circuit path and diverts the excessive harmonic current away from the downstream loads into itself. It then nullifies and thus eliminates the harmonic current within the three-phase passive harmonic filter.

4. Second, the grid being relatively a lower impedance path, absorbs the remaining leftover harmonics after the absorption by the downstream equipment and machinery. A harmonic filter, either an active filter or a passive harmonic filter, prevents these harmonics from going over to the upstream grid.

The benefits of Passive Harmonic Filter with super tuned specification

1. It Eliminates equipment Failure and voltage fluctuation Tripping, as explained in the above paragraph.

2. It Prevents Arc Flash and Electrical Blasting. Refer to the VFD Harmonic case study.

3. It Reduces the running temperature of equipment. We have achieved up to 5 to 10deg.C reduction in high capacity VFD Drives, transformers, motors and busbars.

4. It Reduces CAPEX and equipment footprint by eliminating the need for costly derating.

5. It Reduces OPEX, first by reducing footprint and then by enhancing the energy efficiency.

6. It Reduces end product quality rejection. We have achieved up to a 50% reduction on a six-sigma scale.

Why a Passive Harmonic Filter is an extraordinary troubleshooter?

1. It alters the dynamics of the harmonic flow by creating a Short-Circuit path for the flow of harmonic frequencies like 250hz for 5th harmonic etc.

2. The load harmonics now, instead of getting absorbed in the downstream loads, are diverted as soon as it’s produced through this short-circuit path into the filter, thus solving equipment failures, tripping, and malfunctions. It allows only a small harmonics within a limit over to the grid, meeting the IEEE 519 harmonic standard, for both voltage and current harmonics.

3. Besides, it's a stored energy LC power bank which will oppose any momentary change in voltage fluctuation, either sag or swell and power surge which may originate either within the plant or outside in the grid. A passive harmonic filter is an indispensable tool in eliminating nuisance tripping of critical plant equipment - process drives, control system, computers, server to name a few.

4. By relieving the downstream equipment from the burden of harmonic absorption, it eliminates that need for costly de-rating saving CAPEX and equipment footprint cost.

5. It saves OPEX cost in the manifold. Firstly, it eliminates harmonics naturally and allows full load plant operation sustainably. Secondly, it troubleshoots failures and thirdly it enhances energy efficiency.

6. The harmonious operation with the optimum power quality results in lesser end-product quality rejections which we have tracked up to 50% savings on Six-Sigma Scale.

Why direct corporate clients choose super tuned Passive Harmonic Filter.

1. There's no one like it before and someone that you like has arrived. We pride in manufacturing the most Beautiful passive harmonic filter, the super tuned type.

2. Its beauty is a deception. It's a monster. It mercilessly Slashes down harmonics as no one did before.

3. It's Rough and Tough (IP55) to withstand a harsh environment. Unlike an active harmonic filter, it does not need an air-conditioned room installation.

4. It's 50kA, 1sec Short-Circuit proof, and Basic Insulation Level (BIL) compatible for 12kV/ 4kV. That can withhold Arc-Flash hazard.

5. This beauty is forever. Its design life is over 40-years.

6. It's Fully Automatic, Variable and adjusts with process load variations and harmonic distortions in the power system.

7. Thanks to you for being our 350+ corporate clients, believing in it and every time designing your project with it. Your trust in us, over three decades, has catapulted Encon's passive harmonic filter as the most valued brand in today's world market.