VFD Harmonic caused drive failure and Arc Flash

VFD Harmonic

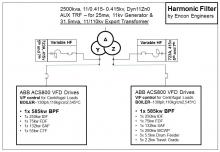

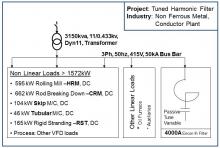

When VFD drive is sizeable or many, the excessive heat and power surge due to VFD harmonic generated high waveform distortion causes drive failure and unwanted tripping. Read this case study how harmonic filter for VFD solved the problem including an arc flash incident whose root cause detailed in another webpage "harmonic filter powerful with super tuned specification".