Performance linked energy conservation project was carried out at Coca Cola, Bidadi, Bangalore which had a production capacity of over one million cases per month. Major energy savings were achieved with its refrigeration plant through process optimization which is a NO-COST implementation measure. Please visit "Making of a Green Building Code" for its methodology. It was also facing frequent and chronic electronics failures with PET SIDEL m/c and vfd drives in bottling section. Those got eliminated after we installed Harmonic Filter which was designed for the total plant load. We had implemented total power management philosophy for enhancing 3P, Power, Productivity and Profitability.

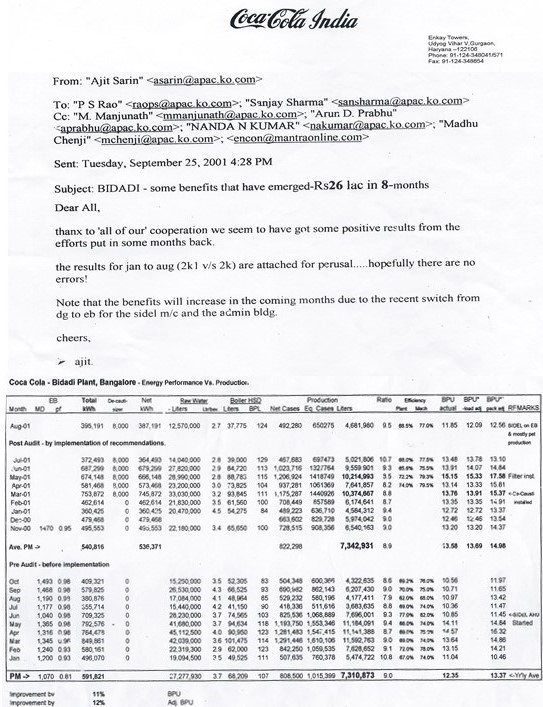

Energy saving results were accounted for 8months before, and 8months after this energy conservation project up to the year 2001. At coca cola overall energy efficiency is measured by BPU, which is one liter of Beverage Production per Unit of energy consumption. Before the energy conservation project its 8months average production was at 808,500cases with 13.37 BPU, And after 8month period, the production increased little by 1.7% to 822,298cases at 14.98BPU. Post implementation net energy savings, as certified by Coca Cola, was (14.98 -13.37 / 13.37) = 12%.