Increase Productivity

Abstract- Harmonic solution is an engineer's approach to total productive maintenance (TPM) to Increase Productivity. No stoppage. No breakdown. No quality rejection. A 3500 TCD sugar milling unit was operating at 3000 TCD due to frequent drive stalling problem with dc mill motor. To increase productivity and sugar recovery, it installed a 2000A passive tuned harmonic filter in 2010, at a 3MW 415V Turbine Generator (TG).

Production increased to 3500 TCD with the same equipment foot print. Achieved 15% energy saving. Harmonic filter allows stable torque across mill motor that increase productivity substantially. Sugar recovery increased from 10.8% to 11.2%. It became the highest recovery sugar plant in the region. It had a 3 MW, 415V TG supplying to cane preparation and dc mill drive sections. It included 4nos 450 kW DC Mill Drives, 2nos 560 kW AC SRIM motor Fiberizer drives, 225 kW Leveller and 187 kW Chopper. The second 6 MW, 11kV TG was meant for uninterrupted excess power export to the grid. Through a 3.15 MVA, 11kV/ 415V, Dyn11 transformer it supplies power to boiling house, sugar house and power plant's auxiliary load.

In 2015, it attempted even a higher crushing rate at lesser than 650 RPM mill motor speed for optimum sugar recovery. But the mill motors were hunting continuously and stalling frequently. The dc mill motor's trip set was at 1440A dc. A power quality analysis revealed that the dc Mill Drives and Motors were good up to a production capacity of 4500 TCD. To achieve this, we recommended installing harmonic filter across each dc mill drive. The factory decided to implement it in stages. In 2016, it installed 2nos harmonics filters at Mill no.1 and Mill no.4.

Production increased to 4000 TCD and the mill drives were tested down to 538 RPM speed for even a better sugar recovery. The input ac current to dc mill drive slashed from 1000 to 500A. The dc output current from thyristor drive to dc mill motor remained stable at 1000A dc. It was exceeding its trip set value of 1440A and causing the mill motor to stall.

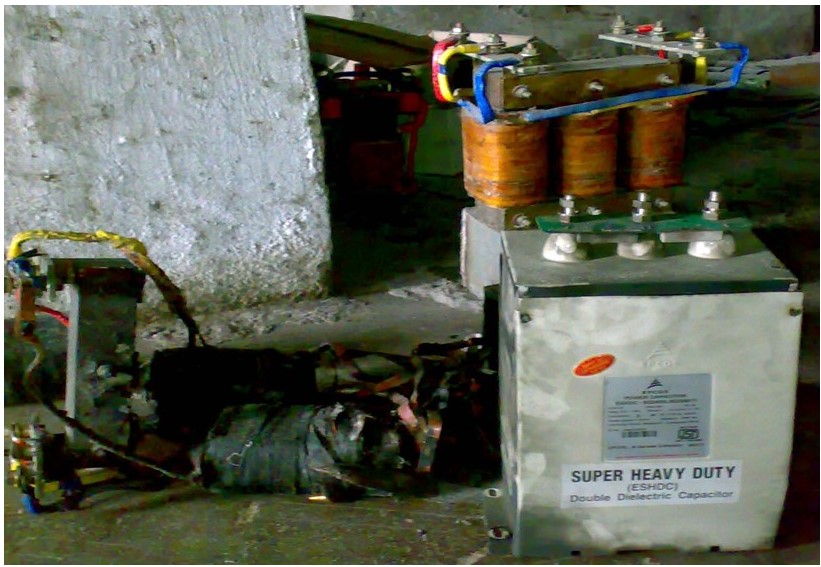

Installing drive end harmonic filter, as shown in the caption picture, eliminates ac ripples from dc power supply. Otherwise, it adds up to the dc motor's input current. Causes high current fluctuation with the dc motor. In turn, it causes fluctuations with the motor's output torque. Its effect would trigger the dc drive to stall the mill motor. In-addition, the fluctuating dc mill motor torque would cause lower sugar recovery at a higher energy consumption.

Index Terms- power quality harmonic study, drive failures, electronics failures, de-tuned filter blasting, electrical failures, debottlenecking production capacity, increasing sugar recovery, power system harmonics, harmonic filter.

I. NOMENCLATURE

THDi, Total harmonic distortions, current

THDv, Total harmonic distortions, voltage

In, Individual current harmonic orders, like 3rd is I3

Vn, Individual voltage harmonic orders, like 5th is V5

Siemens 6RA22 is an OEM trademark for DC Drive.

II. INTRODUCTION

At 3500TCD crushing rate 3mw TG operates at 2.5mw and 6mw TG 5mw out of which 2.2mw is for boiling & sugar house consumptions and remaining 2.8mw is exported to grid through a 6.3mva, 11/33kv grid transformer. The running steam requirement of 75tph, 42kg/cm2, 430oC for both TGs are supplied from 2nos 40tph Bagasse fired Boilers connected at a common supply header. Exhaust steam from TGs are used for the manufacturing process. There is a correlation between the power produced and the process steam requirement; and that's why these types are called Cogeneration Power Plants.

The mechanical mill that extracts the juice from cane runs at between 4.5 to 5.5rpm which is automatically adjusted based on the cane crushing rate. The Primary gear box reduces speed from the initial dc motor's 750rpm to 25.8rpm and then an open type secondary GB reduces it to its final requirement and connects to the mechanical mill. Typical speed setting from mill 1 to mill-4 are 732rpm- 656rpm- 665rpm- 660rpm respectively. Mill-4 speed always remains lowest being the last point of juice extraction. Mill-1 hits the cane first. Mill-1 and Mill-4 always have higher power consumption then other intermediate mills.

Each dc mill duty motor is of IEC make and rated at 450kw, 440Vdc, 1000rpm, 1083A dc current- with 200% overload capacity for 2sec and 150% overload capacity for 2hrs.

Field Excitation V and I = 220v and 24.8A

Armature winding resistance = 0.00320ohm

Shunt winding resistance = 7.5ohm

I.P winding resistance = 0.00190ohm

Compensating winding resistance = 0.000140ohm

Each dc drive is of Siemens 6RA22 type with 2sets of thyristor converters each 1000A in parallel and totaling up to 2000A maximum dc current.

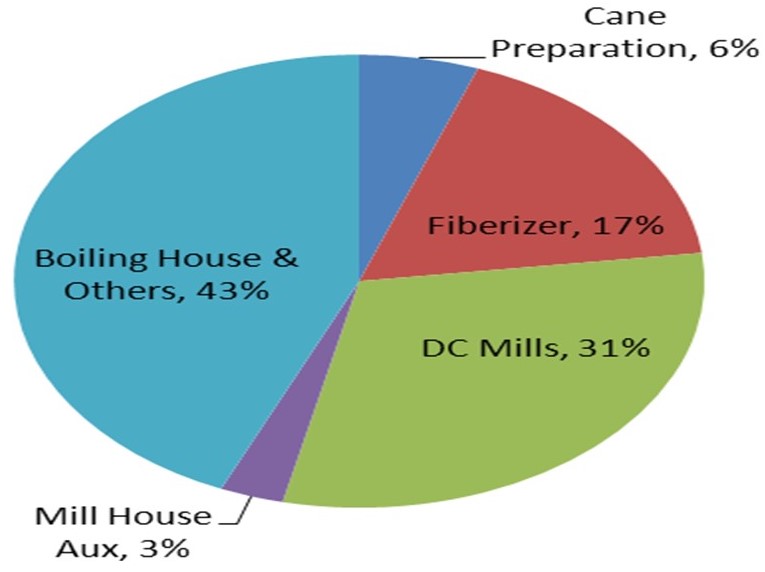

A cane sugar plants energy efficiency is measured in terms of Specific Energy Consumption (SEC) and the optimum SEC, depending upon the types of Mill Drive used, are 19, 21 and 24 kWh per ton of cane for DC, VFD and Hydraulic drives respectively. The SEC for this plant was 27.47 and its energy consumption pie chart was as shown in Fig.5.

III. CASE STUDY

A. Problem Statement and the Implemented Solution

DC Mill motor and drives mostly mill-4 and mill-1 tripped frequently, 3trips per week on a combination of field failures, tachometer feedback failures and high temperature. In addition, dc drive cards, namely A1 control card & A2 Power card along with synchronizing transformer 440v/415v failed frequently.

It started its DC mill drive operation with heavy duty detuned harmonic filters across Fiberizer, Leveler, Chopper, DC Mill Drives and other process loads. Within a few months into the operation, all detuned filters failed with loud blasting sounds. Initially the plant used to replace those failed detuned harmonic filters, but very soon those also were blasted away the same way, as shown in Fig.6.

Harmonics in electrical power system flow into other non-harmonic linear loads like in fixed speed squirrel case induction motors- SQIM. AC motors of various sizes from few hp to mostly up to 100hp failed frequently about 2incidents per week, Motors used to burn with heavy flash, as shown in Fig.7.

Switch gears, mostly switch fuse units- SFUs and moulded case circuit breakers-MCCBs at 3mw TG's main power incomer 415v PCC Panel, used to burn and sometimes even blasted. That apart load end SFUs and MCCBs across AC Motor and capacitor feeders were also burnt or blasted regularly. The 415v main incomer PCC panel is as shown in Fig.8.

The 3mw co-generation power plant's steam turbine was unable to deliver its rated power output and was required to run at a much de-rated capacity. The turbine of this size operates at about 8300rpm, and with a maximum nozzle chest pressure of about 34kg/cm2 for a designed inlet steam pressure of about 42kg/cm2.

When a turbine delivers its rated power output, 3mw for this turbine, only then its nozzle chest pressure reaches near its designed maximum range, 34kg/cm2 for this turbine, and beyond the turbine can no longer deliver additional power and starts hunting. Power system harmonic distortion adds up to additional pressure on the turbine's nozzle chest pressure; its effect increases the nozzle chest pressure rapidly that reaches its designed maximum value at a lesser power output than its designed rated output.

In-addition the 3mw turbine and its 3.75mva alternator was operating at higher temperatures, as both were acting as a sink for the power system harmonics. The source, the dc motors, were also hunting and the motors and its thyristor converters were also operating at higher temperatures.

A detailed Power Quality harmonic measurement was carried out during the year 2012 using a high quality 3phase power quality harmonic analyzer of type PowerPro. The instrument measures at a sampling rate of 256samples/cycle and calculates RMS value of all measured parameters at every cycle basis.

It measures all steady state power parameters and power quality that including individual phase and neutral harmonics up to 64th, Total current harmonic distortion (THDi), Total voltage harmonic distortion (THDv), switching Inrush current, waveforms, voltage and current spikes, sags, swells and voltage fluctuation with 65uS precision recording. Further instrument details could be obtained at www.candura.com.

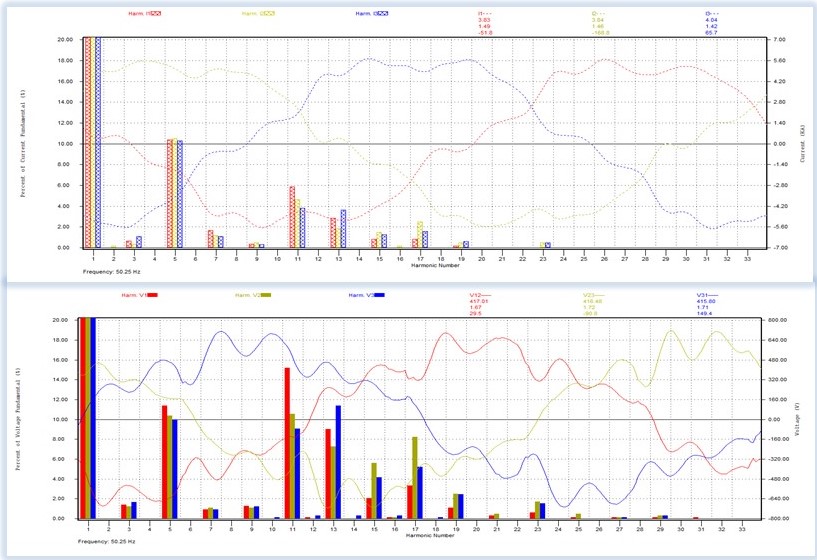

The current and voltage harmonic distortions along with their waveforms at the 415v main incomer PCC Panel for the 3mw 415v TG output power are as shown in Fig.9, before installation of 2000A Tuned Harmonic Filter at the main incomer PCC Panel. Because of major nonlinear loads, mostly in the form of dc drives, the harmonic distortions both voltage and currents were high. The voltage harmonic distortions were much higher than the current harmonic distortions. The total current harmonic distortion (THDi) was at 13.1% with I5, I11, and I13 as major current harmonics. The total voltage harmonic distortion (THDv) was at 23.2% with I11, I5, and I13 as major voltage harmonics.

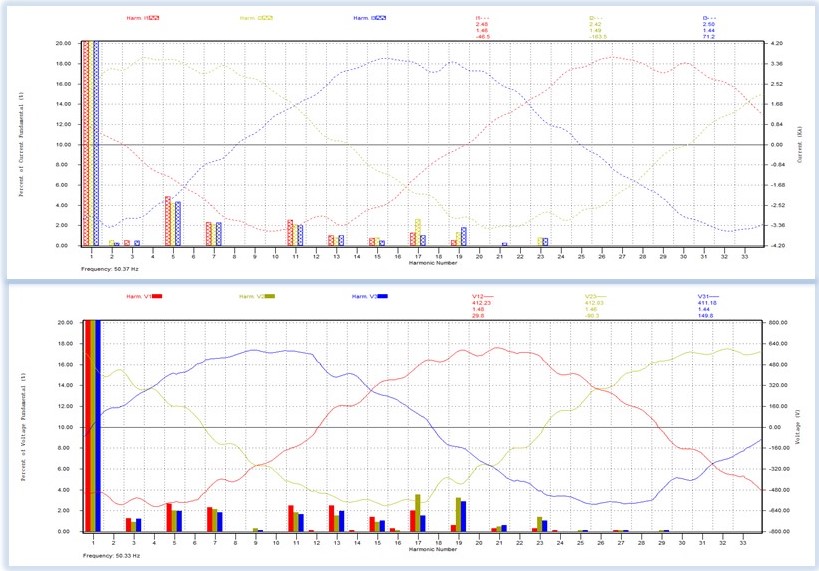

The current and voltage harmonic distortions along with their waveforms at 415v main incomer PCC Panel are as shown in Fig.10, after installation of the 2000A Tuned Harmonic Filter.

Post harmonic filter scenario the harmonic distortions, both current and voltage harmonics, were adequately mitigated. The total current harmonic distortion (THDi) was at 6.8% with I5, I7, and I11 as major current harmonics. The total voltage harmonic distortion (THDv) was at 5.6% with I5, I11, and I7 as major voltage harmonics.

Thereafter in the year 2016, additional two sets each 671A tuned harmonic filters were installed across mill-1 and mill-4 that increased the factory's cane crushing capacity from 3500 to 4000TCD.

In-addition it enabled lower speed operation of the mills which were tested down up to 538rpm for having even higher sugar recovery at increased cane crushing rate.

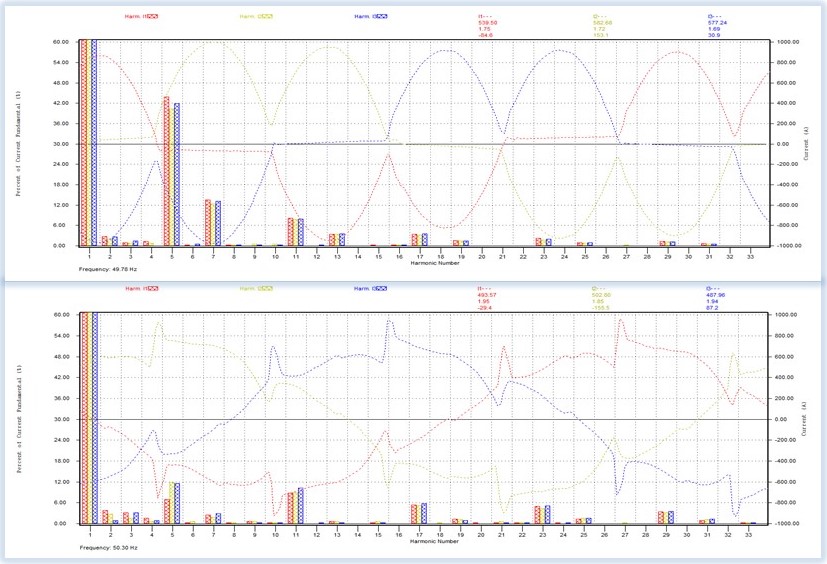

The current harmonic distortions along with their waveforms at 415v incomer of the mill drives' Thyristor Converters are as shown in Fig.11, before and after the installation of the 671A Tuned Harmonic Filter.

Post harmonic filter scenario current harmonic distortions across dc mill drives were adequately mitigated. The total current harmonic distortions (THDi) was at 45.3% with I5, I7, and I11 as major individual current harmonics before harmonic filter installation.

The total current harmonic distortion (THDi) reduced substantially to 17.5% with I5, I11, and I7 as major individual current harmonics after phase-1 and part commissioning of the drive end harmonic filters.

Ordinarily it may seem otherwise but the harmonic reductions were fantastic that by considering the very high initial harmonic lever of 45.3% at 1000A input current. The original harmonic current was 0.453x1000 = 453A. Post harmonic correction the harmonic current reduced to a mere 0.175x500 = 88A. The percentage reduction on the actual harmonic current is thus ((453-88)/453) x100 = 81%, which is a massive reduction.

It is also possible to design an appropriate harmonic filter that could further reduce harmonics but at a higher cost; and such costly harmonic filters are only justified for prolonged equipment failures and tripping on supply voltage fluctuations which was not the case here.

Because of those harmonic distortion corrections, namely voltage harmonics at common 415v TG bus bar and current harmonics both at 415v TG incomer and DC Mill Drives; the factory's all problems associated with lower power generation from the TGs, production loss, lower sugar recovery, and the never ending and scary electrical blasts, all got eliminated and did not repeat thereafter.

Apart from power quality harmonic measurements and the documented performance test, we also tracked other physical evidences to the extent it occurred to us during harmonic filter commissioning. Physical verification is an essential process for an effective troubleshooting engineer. These feedbacks are the difference between a "job well done" and a "job is in process".

Before commissioning the harmonic filters for the dc mill drives we gauged the dc motors running temperature along with client's engineer. We were unable to touch our full palm on the dc motor body even for a few seconds. One week after harmonic filter commissioning, we could touch the same dc motor body at the same point for minute long.

We also observed that the reductions in noise, vibration, and running temperatures in all equipment connected at the same power system, including the 3mw turbine and its 3.75mva alternator, were all distinctly recognizable and found to be quiet substantial.

IV. CONCLUSION

The enumerated case study and its years long performance verification report clearly establish all round improvement of major power system parameters for the plant's total power management, safety and avoiding electrical blasts.

Going by the saying what goes around comes around, it reconfirms the fact that doing power quality engineering at the downstream at the point of harmonic generations of the DC drives either collectively or individually, which is at 415v in this case study, mirrors optimum power system stability both within the localized equipment like in the dc mill motors and within the connected power supply zone of the 3mw TG.

Such an engineering effort prevents electrical harmonic pollutions from entering the electrical power system of the TG's supply zone which could then percolate into other equipment connected at the same electrical power system. That creates problems of electrical blasts, tripping and equipment failures.

In-addition, it reduces carbon emission by enhancing productivity, removing barriers to energy efficiency, and promoting efficient use of energy all along. That starts from downstream plant to all equipment loads, and up to the upstream cogeneration power plant.

The cost of energy savings when looked narrowly in comparison with the electricity bill alone, might seem moderate but when compared holistically with substantially reduced investment cost on enhanced production, substantial increase in profitability on the improvement in product quality which here is the increased sugar recovery, lower carbon footprint, uninterrupted production, MTBF, inventory cost of components and workforce motivation coupled with the ever rising cost of energy, the economic benefits far outweigh the cost of the solution.

V. BIOGRAPHIES

V. BIOGRAPHIES

Kanai Banerjee graduated in Electrical Engineering from Indian Institute of Engineering Science and Technology, Shibpur, India in the year 1983. Worked at Bharat Heavy Electricals Limited from 1983 to 1995 and thereafter until date, as a promoter at Encon Engineers (www.enconengineers.in/) at Bangalore.

His special fields of interest include power quality engineering, harmonic solutions and manufacturing passive tuned harmonic filter and triplen harmonic filter of all size LV and HV, troubleshooting failures, energy conservation, electrical consultancy and HVAC engineering for setting up truly green building and retrofitting large centralized HVAC projects.

He has been instrumental in building up the company's impressive growth and reputation as a knowledge-based technology solution provider on power quality, energy efficiency, process optimization and in Total Power Management fields.

An energy auditor certified by the bureau of energy efficiency under the ministry of power government of India, a member and chartered professional engineer with the institute of engineers India, a member at the Indian society of heating, refrigerating and air-conditioning engineers, ISHRAE and a member at the Canadian and American EMTP-ATP user group.

Place: Bangalore

Date: 30 March 2012