Optimization of Slip Ring Induction Motor in Fiberizer Drive in a Sugar milling unit - after HARMONIC FILTER INSTALLATION: The overall energy efficiency of a 5000TCD cane sugar mill with a 25mW co-generation power plant and 31.5MVA, 11kV/110kV grid synchronization transformer, improved by 14.3% to 19.1units per ton of cane crushed from its earlier level of 22.3units. How was the energy saving achieved? Well, in this case study we shall find that out with sugar industry's most sensitive and yet rough and tough drive load, the Fiberiser. It's sensitive. Gap setting is important. But equalizing its vibrating torque is challenging, and that is something not done by default. Adding inappropriate rotor resistance would turn it into an energy guzzler. What compounds the problem further is, it's the first line of process that confronts with the untamed cane from field.

What about adding a Fly Wheel, an electrical fly wheel at its motor terminal? How do we verify its efficacy for energy savings? Well, this case study is just about that. Tuned and passive harmonic Filter is a perfect electrical fly wheel being an energy storage device, as shown in Fig.1, unlike the active harmonic filters which are not designed to store energy. Passive harmonics filter slashes down the motor starting inrush current and equalizes motor torque vibrations at its normal running even with a bed of untamed cane feeding. The philosophy of starting inrush current reduction is also applicable in optimizing running load fluctuations which are like mini starting inrush currents. Overall, it slashed down the Fiberizer drive consumption by 10.2% to 3.74units per ton of cane crushed from its earlier figure of 4.17units. In-addition to effecting energy conservation, the optimized and balanced load torque characteristics at the motor terminal, enhanced the plant's cane crushing capacity by 30% with the same equipment footprint.

Let's look at the recorded RMS graphs associated with motor start inrush currents before, and after, the motor start. These power system measurements were done after the installation of passive harmonic filter. The Fiberizer drive was driven by a set of 2nos each 850kW, 11kV, 960rpm, 50Hz SRIM from two opposite sides. Thus, it was possible to measure the motor starting inrush current from cold start at zero shaft speed and as well from a speed start at rated shaft speed. The motor's full load running current was 26.25Amps with 3phase, 11.0kV, 50hZ supply voltage.

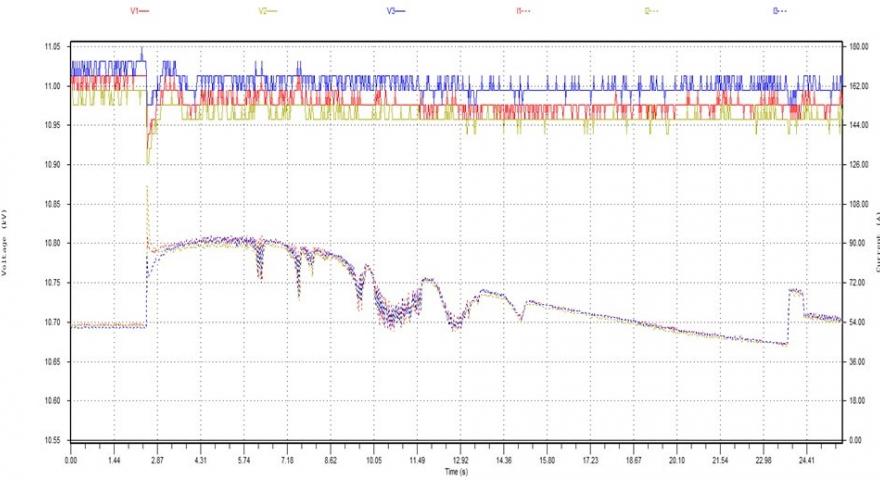

Cold Motor start from zero shaft speed: The above caption picture is RMS snapshot view of the high voltage slip ring induction motor's staring inrush current graph. The 3phase voltage at motor terminal before and after the motor start with harmonic filter installation was 11.01kV/ 11.98kV/ 11.03kV and 10.93kV/ 10.90kV/ 10.97kV. The peak voltage sag/dip was 0.73%.

The 3phase current at motor terminal before and after the cold motor start with harmonic filter installation was, 52A/ 52A/ 52A (which were the currents from the passive harmonic filter) and 82.42A/ 116.61A/ 83.64A. The peak motor starting current was 4.44 times (down from 6.81 times before the installation of passive harmonic filter) for a few milliseconds. Total motor start duration was 24Sec during which the peak staring current decreased gradually as like a drooping characteristic.

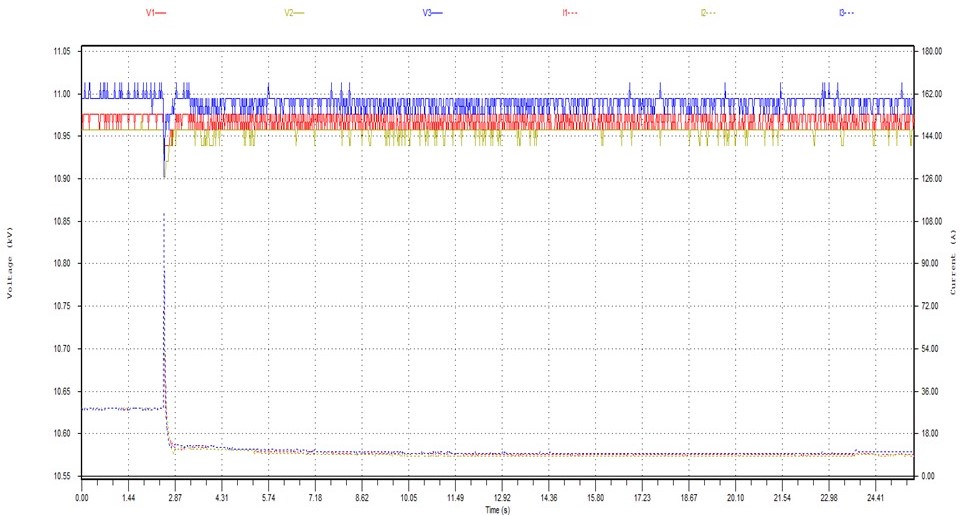

Speed Motor start from the rated shaft speed: Fig.2 is RMS snapshot view of the high voltage slip ring induction motor's staring inrush current graph. The 3phase voltage at motor terminal before and after the motor start without harmonic filter installation was 10.97kV/ 10.95kV/ 10.98kV and 10.92kV/ 10.90kV/ 10.90kV. The peak voltage sag/dip was 0.72%.

The 3phase current at motor terminal before and after the motor start without harmonic filter installation was, 26.25A/ 26.25A/ 26.25A and 87.91 -26.25/ 68.38 -26.25/ 112.33 -26.25 = 61.66A/ 42.13A/ 86.08A. The peak motor starting current was 3.28 times (down from 5.58 times before the installation of passive harmonic filter) for a few milliseconds. Total motor start duration was 100milli Sec during which its peak staring current decreased sharply but also as like a drooping characteristic.